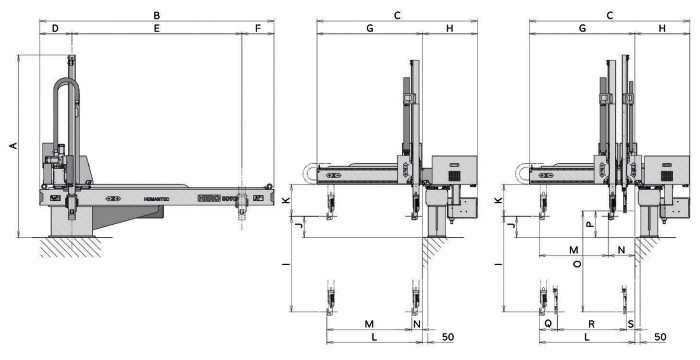

External dimensions

| Model | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HERO 308 | 1567 | 2006 | 1310 | 303 | 1400 | 303 | 774 | 517 | 800 | 200 | 300 | 700 | 600 | 100 | |||||

| HERO 308D | 1617 | 450 | 250 | 850 | 250 | 150 | 450 | 80 | |||||||||||

| HERO 509 | 1667 | 2206 | 1510 | 303 | 1600 | 303 | 994 | 517 | 900 | 200 | 300 | 900 | 800 | 100 | |||||

| HERO 509D | 1717 | 650 | 250 | 950 | 250 | 170 | 650 | 80 | |||||||||||

| HERO 511 | 1867 | 2406 | 1610 | 303 | 1800 | 303 | 1094 | 517 | 110 | 200 | 300 | 1000 | 900 | 100 | |||||

| HERO 511D | 1917 | 750 | 250 | 1150 | 250 | 170 | 750 | 80 |

Dimension unit: mm

OPTION: MAINTENANCE STAGE (ONLY HERO 20)

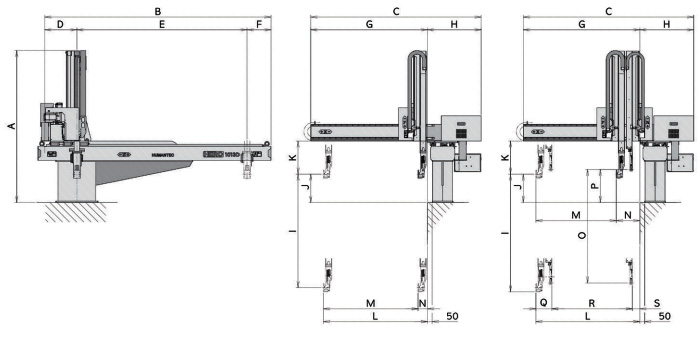

| Model | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HERO 1013 II | 1560 | 2666 | 1804 | 413 | 2000 | 253 | 1234 | 570 | 1300 | 250 | 350 | 1100 | 1000 | 100 | |||||

| HERO 1013DII | 850 | 250 | 1300 | 300 | 170 | 850 | 80 | ||||||||||||

| HERO 1015 II | 1660 | 2666 | 1804 | 413 | 2000 | 253 | 1234 | 570 | 1500 | 250 | 350 | 1100 | 1000 | 100 | |||||

| HERO 1015DII | 850 | 250 | 1500 | 300 | 170 | 850 | 80 | ||||||||||||

| HERO 2016 II | 1920 | 3210 | 2225 | 455 | 2400 | 355 | 1635 | 590 | 1600 | 350 | 450 | 1500 | 1300 | 200 | |||||

| HERO 2016DII | 1200 | 300 | 1600 | 400 | 200 | 1200 | 100 | ||||||||||||

| HERO 2018 II | 2020 | 3210 | 2225 | 455 | 2400 | 355 | 1635 | 590 | 1800 | 350 | 450 | 1500 | 1300 | 200 | |||||

| HERO 2018DII | 1200 | 300 | 1800 | 400 | 200 | 1200 | 100 | ||||||||||||

| HERO 3520 II | 2570 | 4610 | 3200 | 605 | 3500 | 505 | 2450 | 750 | 2000 | 500 | 700 | 2100 | 1800 | 300 | |||||

| HERO 5025 II | 2870 | 3210 | 3350 | 630 | 4000 | 530 | 2600 | 750 | 2500 | 500 | 750 | 2200 | 1800 | 400 |

Basic Specifications

| power | working pressure | driving method | Payload (kg) | repeatability | controller |

|---|---|---|---|---|---|

| AC220V, 50/60Hz | 0.5MPa (5kgf/cm²) | AC SERVO MOTOR | 3~50 | 0.1mm | H1 |

General specifications

Dimension unit: mm

OPTION: MAINTENANCE STAGE (ONLY HERO 20)

| Model | Driving | before and after P | P up and down | before and after R | R up and down | air consumption (Nℓ/CYCLE) |

Power facility capacity (kVA) |

payload (kg) |

|---|---|---|---|---|---|---|---|---|

| HERO-3□□ | 1400 | 700 | 800 | - | - | 3.0 | 2.6 | 3 |

| HERO-3□□D | 450 | 450 | 850 | 3.4 | ||||

| HERO-5□□ | 1600 (1800) |

800 (900) |

900 (1100) |

- | - | 4.0 | 2.6 | 5 (OP: 8) |

| HERO-5□□D | 650 (750) |

650 (750) |

950 (1150) |

3.4 | ||||

| HERO-10□□II | 2000 (2400) |

1000 | 1300 (1500) |

- | - | 10.0 | 3.8 | 10 (OP: 15) |

| HERO-10□□DII | 850 | 850 | 1300 (1500) |

5.4 | ||||

| HERO-20□□II | 2400 (2700) |

1300 | 1600 (1800) |

- | - | 15.0 | 5.3 | 20 (OP: 30) |

| HERO-20□□DII | 1200 | 1200 | 1600 (1800) |

7.6 | ||||

| HERO-35□□II | 3500 (4000) |

1800 | 2000 | - | - | 65 | 7.3 | 35 |

| HERO-50□□II | 4000 (4500) |

1800 | 2500 (3000) |

- | - | 80 | 7.3 | 50 |

Convenience function

Full automatic connection

Automatic start and stop waiting in conjunction with the injection molding machine

blind function

Blind display of unused setting values linked to mode

keep pretending

When a chuck miss occurs, the product is dropped and moved to the standby position.

When the injection machine is restarted, fully automatic operation continues

Permission setting

Individual authorization for 4 users is possible

Ejector-free function

When the product is chucked and closed, it is pushed by the ejector force in an am-free state

User program function

Users can add/edit programs they want with various commands

controller

※ Using H-1 CONTROLLER

7inch TFT Touch Screen(800X480)

3-step select switchcan be operated quickly with

3 languages switchable / absolute motor application

many options available / status LED mark